A bioreactor is a device that mixes the culture medium during microbiological synthesis. Creates optimal conditions for the vital activity of cells and microorganisms cultivated in it - it provides respiration, supply of food and removal of metabolites due to uniform mixing of the gas and liquid components of the bioreactor contents.

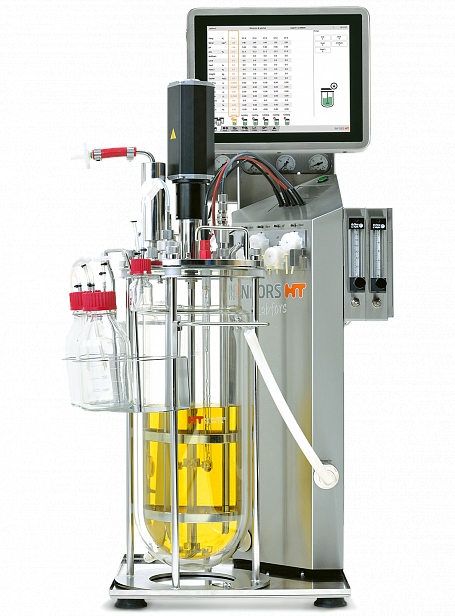

For example Bioreactor Labfors 5 from INFORS (Switzerland) is a leading manufacturer of bioreactors, shakers for incubators. The company occupies a leading position in the production of laboratory equipment. Labfors 5 from INFORS is a bioreactor that can be adjusted for a specific bioprocess, it is possible to carry out cultivation with feed or in continuous modes.

Used by:

- Biotechnology

- Cell technologies

- Molecular biology

- Culture media production

- Cultivation of cells, microorganisms, phototrophic organisms

- Cultivation of solid substrates and enzymatic bioprocesses

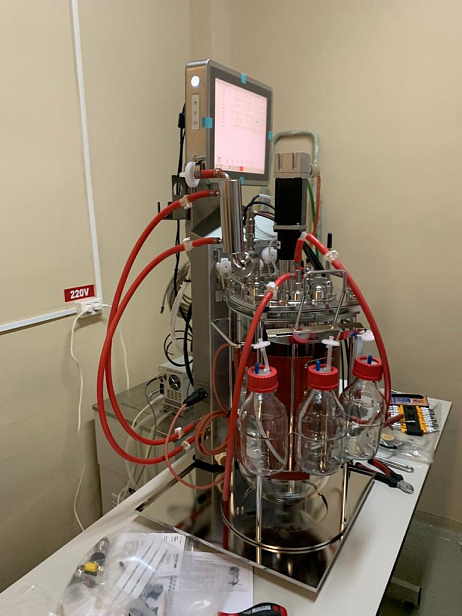

We received the project for the delivery of such a bioreactor at the stage of commissioning. We needed an engineer with experience in installing and configuring this reactor. Time for assembly is 6 hours, to set up and start up - 8 hours.

During unpacking, you need to check all glass flasks and adapters for integrity, everything was whole, thanks to the original packaging. During the assembly, no problems or defects were identified, the instructions were followed and everything went well. When installing the bioreactor, it is necessary to choose a flat place without a slope, set the table to a level.

Labfors 5 - equipped with the latest software version with the ability to connect remotely via the Internet, using this software, you can monitor the fermentation parameters and remote configuration / management with saving reports in the cloud storage. This function is free in the 1st year of use, in the future you need to pay, discussed when ordering.

Controlled parameters:

- stirrer rotation speed

- temperature

- рН

- dissolved oxygen concentration (option)

- foam level control (optional)

- gas mass flow control

- gas mixing system - GasMix (option)

- control on / off. oxygen supply valve

- flue gas analysis (O2, CO2)

- continuous cultivation feeding

- optical density

- redox potential

- weight

- pressure

- analysis of the substrate (for example, glucose and methanol levels), etc.