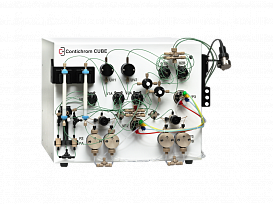

Features:

- Adjustable flow rate, ml / min - 0.1-100;

- maximum working pressure, bar - 50;

- possibility of simultaneous connection of up to 16 buffer solutions;

- optical module UV, nm - 260/280;

- measured range of concentration of hydrogen ions, units. pH - 1-14;

- measured range of electrical conductivity, mS / cm - 1-150;

- dimensions, W × D × H, mm - 509 × 450 × 370;

- weight, kg - 30.

Chromatographic systems of medium pressure Contichrom from Chromacon (Switzerland) allow purification of biomolecules both in a standard way, based on the use of discontinuous (Batch) processes, and using methods of continuous preparative chromatography, including separation of binary mixtures in a "pseudo-moving" sorbent layer (Simulated Moving Bed, SMB) and Multicolumn Countercurrent Solvent Gradient Purification (MCSGP). Unlike the traditional Batch methodical approach, when using the SMB and MCSGP methods, the separation of binary or multicomponent mixtures is carried out by means of continuous multiple purification and concentration of the target product in a storage column.

The main stages of planning and carrying out the MCSGP procedure for the chromatographic separation of complex multicomponent mixtures:

- identify the peak of the investigated product according to the results of the preliminary chromatographic procedure and save the obtained chromatogram in the database;

- using the Contichrom software setup wizard, the boundaries of the peak of the pure target product and the gray zone, including the area of its contamination with foreign impurities, are determined. Then designate and fix in the taskbar of the chromatograph the start and end points of the recycles of the purification of fractions;

- start the process of carrying out automatic fine purification of the target product using MCSGP.

The use of this technique provides a high degree of purification of the target biomolecules (99% and higher) and the completeness of their extraction from the feedstock. Compared to traditional chromatography methods, MCSGP and SMB allow an order of magnitude increase in the productivity of preparative purification of the target product and save up to 70% of the reagents used.