At startup, the system cleans and sterilizes the bioreactor in 3 hours. Reliable and reproducible cleaning with alkali and / or acid is performed automatically with changing cycles. It is also quite convenient to carry out cleaning during off-hours, at night. The next day, the bioreactor is immediately ready for the next cultivation. This cleaning method complies with GMP standards.

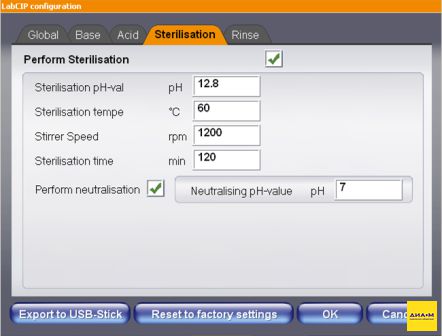

An example is the sterilization of the Labfors 5 with hot sodium hydroxide solution and the final rinse with sterile water (integrated sterile filter). This work is done automatically. The flushing cycle includes all parts of the bioreactor, including the air supply and drainage system. Typical sterilization conditions are: 60 ° C, pH 12.8, duration 3 hours.

Features:

- automatic cleaning (CIP)

- automatic sterilization (SIP)

- high performance

- simple use

- reliable technology proven over the years

- small dimensions (210 mm x 295 mm x 600 mm)

- profitability

- acid and / or alkali cleaning parameters

- sterilization parameters

- pH value

- temperature

- time

- number of cycles